Environment Protection Activities

- home

Sustainability

Eco-Friendly Management

Environment Protection Activities

- Environmental Management System

- Fine Dust Reduction Policy

- Air Environment Management

- Water Quality Environmental Management

KOMIPO Systems Responding to Environmental Issues, Climate Change, Fine Dust, etc.

Green Management Frontier Enterprise, Creating New Value Reliable Enterprise, Creating the Future Growth Foundation and Contributing to the Development of Regional Community

Environmental management is a system that guides execution of a series of management activities to realize continuous environmental achievements across all corporate management processes. The International Organization for Standardization enacted an international standard, ISO 14001 (Environmental Management), that requires objective assessments and certifications from a third-party certification agency.

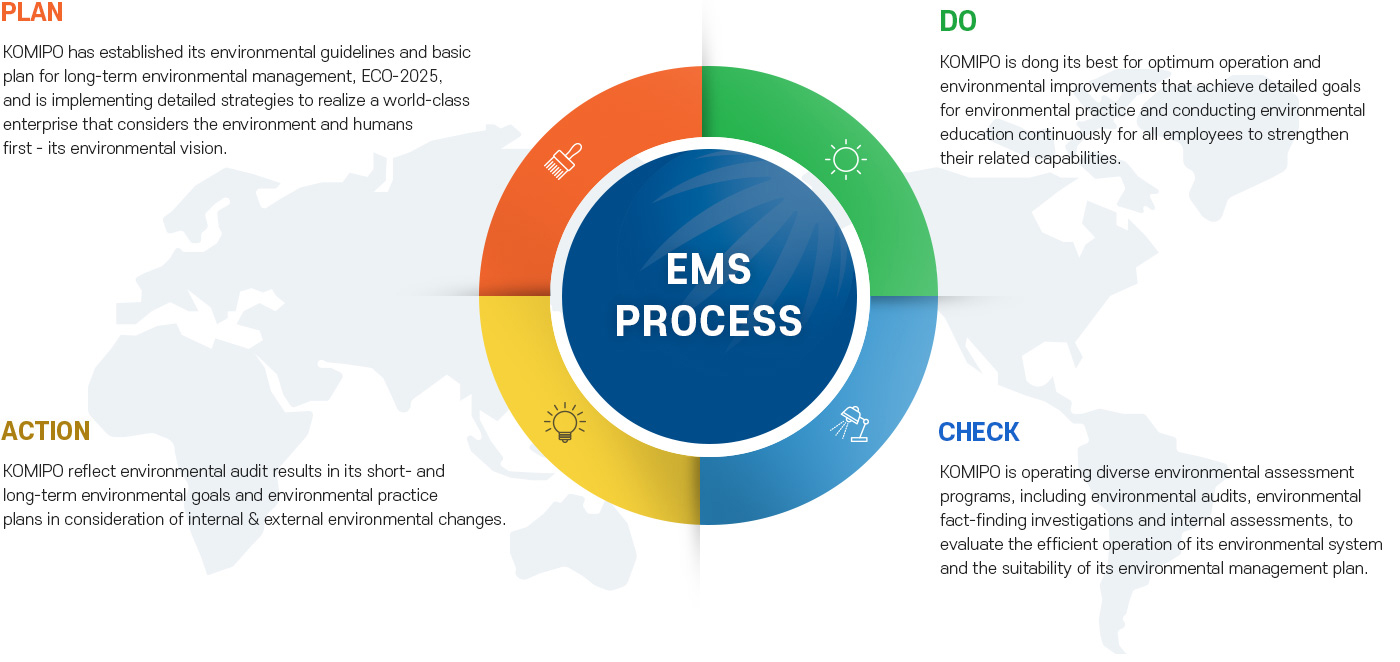

EMS (Environmental Management System) Process

With its acquisition of ISO 14001 in 2004, KOMIPO prepared the foundation for an environmental management system. Since then, as a result of having promoted continuous environmental improvements with the participation of all its employees, KOMIPO has been maintaining ISO 14001 certification through annual evaluations of its post-environmental management system. KOMIPO's environmental management system is operated under a systematic improvement process - PLAN, ACTION, DO, and CHECK.

- EMS PROCESS

- PLAN. KOMIPO has established its environmental guidelines and basic plan for long-term environmental management, ECO-2025, and is implementing detailed strategies to realize a world-class enterprise that considers the environment and humans first - its environmental vision.

- DO. KOMIPO is dong its best for optimum operation and environmental improvements that achieve detailed goals for environmental practice and conducting environmental education continuously for all employees to strengthen their related capabilities.

- CHECK. KOMIPO is operating diverse environmental assessment programs, including environmental audits, environmental fact-finding investigations and internal assessments, to evaluate the efficient operation of its environmental system and the suitability of its environmental management plan.

- ACTION. KOMIPO reflect environmental audit results in its short- and long-term environmental goals and environmental practice plans in consideration of internal & external environmental changes.

Environmental Audits

KOMIPO conducts an environmental audit every year that assesses the efficient operation of its environmental management system and suitability of its environmental management plan to minimize potential environmental risks. In particular, in order to improve weak environmental areas and induce active environmental management, KOMIPO implements both technical checks and internal assessment systems related to the environmental area at its power plants. KOMIPO addresses the environmental audit results immediately after evaluating each case or reflects them in its medium & long-term environmental goals and annual environmental practice plans.

scroll

| Category | Examination Org. | Target | Green Enterprise Post-Examinationt Period |

|---|---|---|---|

| Green Enterprise Post-Examination | Ministry of Environment | All Power Generation Site Divisions | One time/year |

| ISO 14001 Certification | Korean Standards Association | ||

| ISO 140001 Internal Assessment | KOMIPO | ||

| Environmental Management Fact-Finding Investigation | KOMIPO | ||

| Environmental Management Internal Assessment | KOMIPO | ||

| Checks by External Organizations | Competent Local Autonomous Bodies, Police Stations | Frequently |

Green Enterprise Designation

A Green Enterprise is designated by the Ministry of Environment after rigorous examinations by related experts of those enterprises actively striving to minimize environmental pollution with the participation of all employees based on the environmental management resolution of the CEO. KOMIPO Incheon Power Generation Site Division, Jeju Power Generation Site Division and Seocheon Power Generation Site Division received Green Enterprise designation in 1996, 2003 and 2008, respectively, and Sejong Power Generation Site Division and Shin Boryeong Construction Site Division also plan to challenge for the designation, expanding KOMIPO's Green Enterprise-designated power generation site divisions.

scroll

| Power Plant | Validity Period | Designation Org. | Remarks |

|---|---|---|---|

| Incheon Power Generation Site Div. | Mar. 11, '16 ~ Mar. 11, '19 (3 years) | Ministry of Environment | 7 times continuously since '96 |

| Jeju Power Generation Site Div. | Apr. 28, '16 ~ Apr. 27, '19 (3 years) | Ministry of Environment | 4 times continuously since '03 |

| Seocheon Power Generation Site Div. | Feb. 28, '16 ~ Feb. 07, '19 (3 years) | Ministry of Environment | 3 times continuously since '08 |

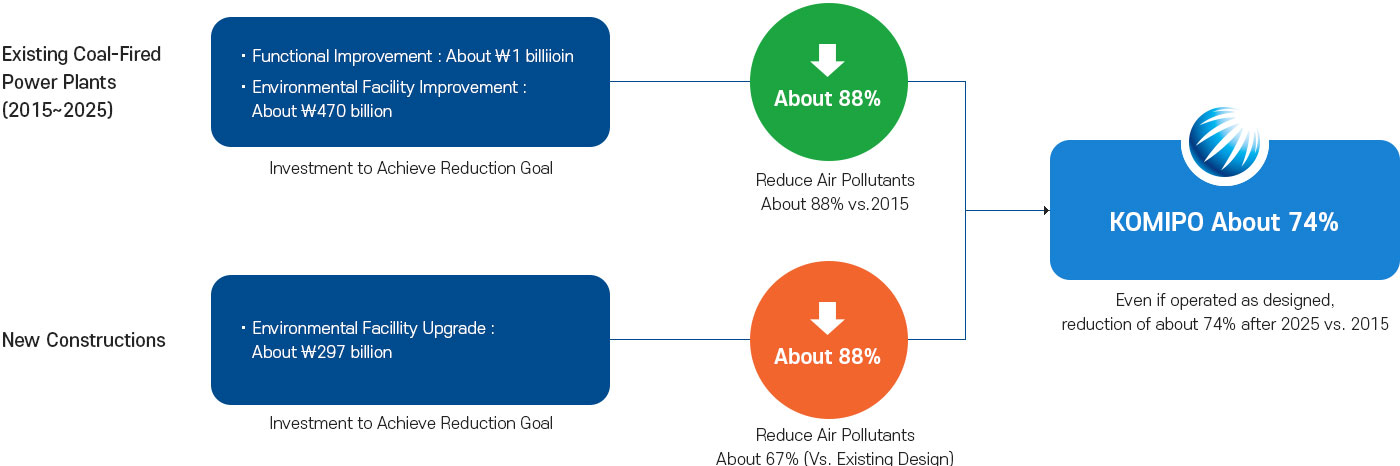

KOMIPO to Reduce Fine Dusts 74% (vs. 2015) by 2025

To reduce fine dust emissions dramatically from its coal-fired power plants, KOMIPO is replacing the environmental facilities in operation at its power plants with the world's top-level facilities as well as updating the design of new power plants under construction.

Expected Effects from Fine Dust Reduction Policy

plans to invest about ₩1 trillion for the functional improvement of main equipment at existing coal-fired power plants and about ₩470 bilKOMIPO lion for improvement of environmental facilities by 2025, reducing emission of air pollutants about 88% (2015 vs. 2025). The company also plans to invest about ₩297 billion for improvement of environmental facilities for Shin Seocheon TPP and Shin Boryeong TPP, which are under construction, with optimum pollutant-prevention facilities, reducing emission of pollutants about 67% over. existing designs. Even if Shin Boryeong TPP #1 & #2 and Shin Seocheon TPP #1, presently under construction, were to be built as previously planned, the emission of air pollutants from KOMIPO's coal-fired power plants after 2025 would be reduced by about 74% after 2025.

- Existing Coal-Fired Power Plants(2015~2025)

- Investment to Achieve Reduction Goal : Functional Improvement - About ₩1 billiioin, Environmental Facility Improvement-About ₩470 billion

- Reduce Air Pollutants About 88% vs.2015

- New Constructions

- Investment to Achieve Reduction Goal : Environmental Facillity Upgrade - About ₩297 billion

- Reduce Air Pollutants About 67% (Vs. Existing Design)

1. Decommission Old Coal-Fired Power Plants & Promote Replacement Construction of LNG Power Plants

scroll

| Power Plant | Completion | Decommissioning Plans |

|---|---|---|

| Seocheon TPP #1 & #2 | 1983 | Sept. 2018 (already reflected in the 7th Basic Plan for Electricity Supply & Demand) |

| Boryeong TPP #1 & #2 | 1984 | 2025 (at the end of lifespan) (to be reflected in he 8th Basic Plan for Electricity Supply & Demand) |

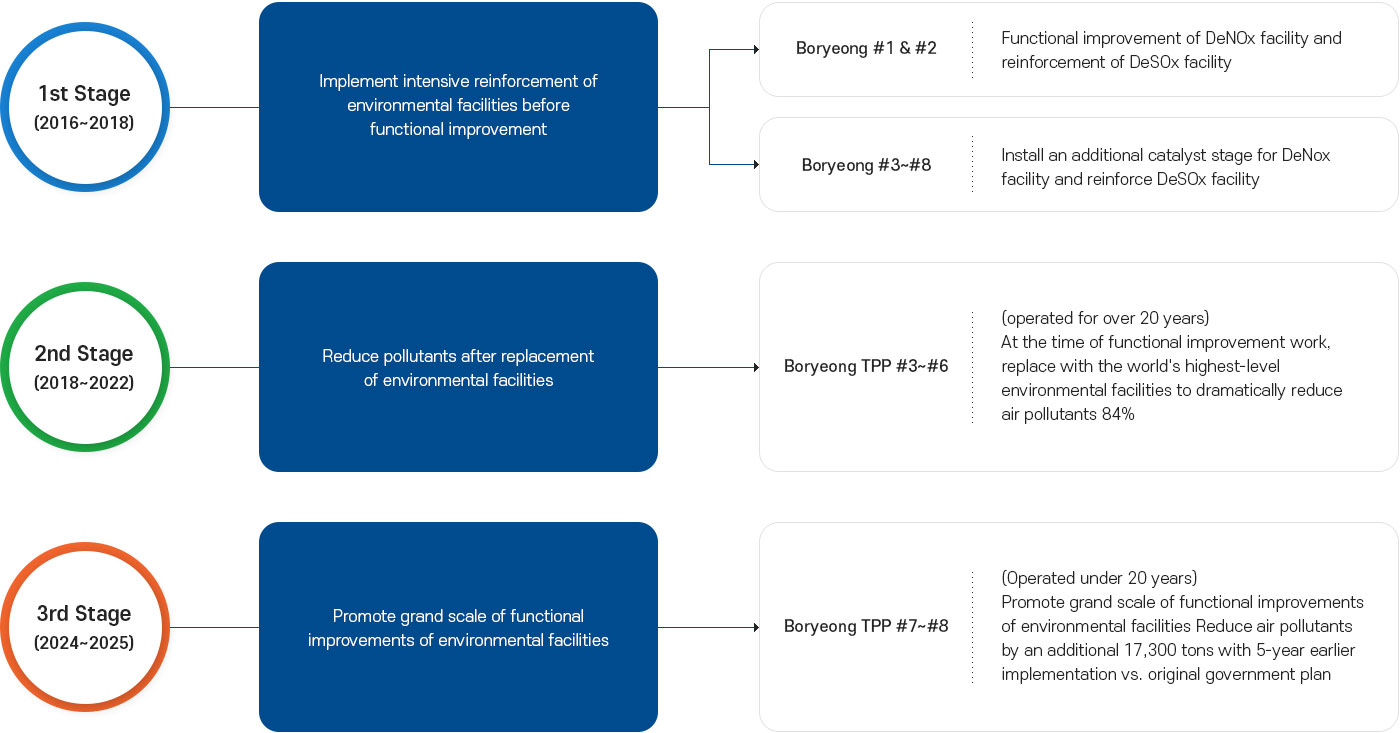

2. Improve Environmental Facilities of Existing Coal-Fired Power Plants (Boryeong TPP #3~#8) to the world's highest level

-

Air Pollutant Reduction Targets of Coal-Fired Power Plants in Chungnam Province

scroll

| Category | Sox (ppm) | Nox (ppm) | Dust (㎎/㎥) |

|---|---|---|---|

| Chungnam Targets (Yearly average) | 15 | 10 | 3 |

| KOMIPO Targets (Yearly average) | 12 | 8 | 2 |

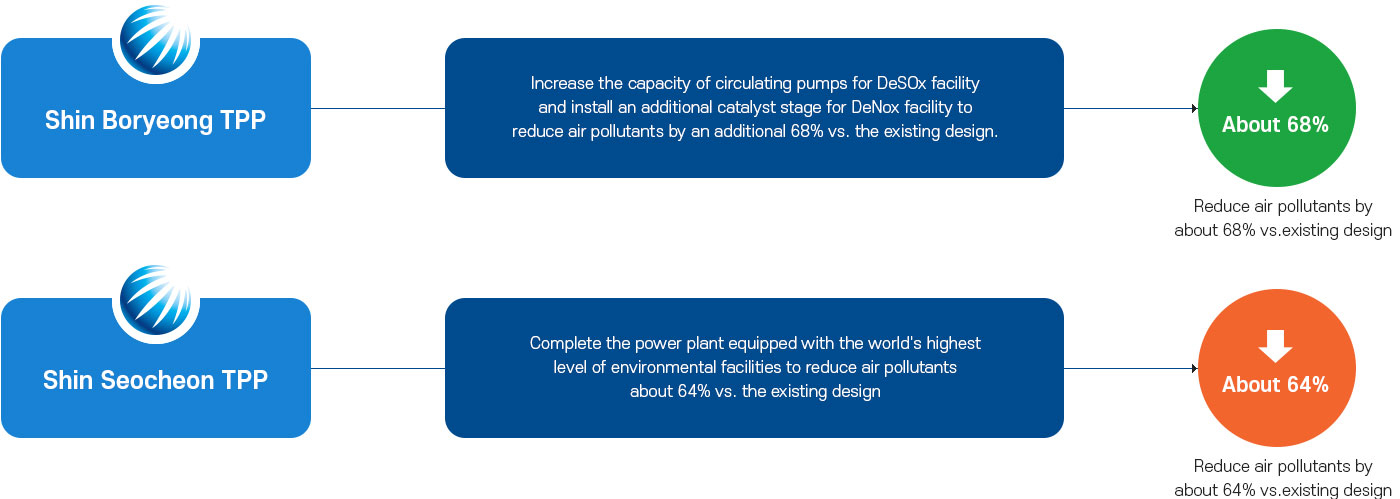

3. Design Change & Facility Improvement to Optimum Prevention Facility Level for Generation Facilities Under Construction

Shin Boryeong TPP : Increase the capacity of circulating pumps for DeSOx facility and install an additional catalyst stage for DeNox facility to reduce air pollutants by an additional 68% vs. the existing design.

Shin Seocheon TPP : Complete the power plant equipped with the world's highest level of environmental facilities to reduce air pollutants about 64% vs. the existing design

Introduce World-Class Air Environment Pollution Prevention Facilities &

Implement Functional Improvements at Existing Facilities

At coal-fired power plants, NOx, SOx and dust are produced in conjunction with the generation of electricity. To minimize the emission of these pollutants, KOMIPO implements functional improvement of environmental facilities at its coal-fired power plants in operation and installs the world's highest level of air environment pollution prevention facilities for new power plants under construction. Of particular note, Seoul Power Generation Site Division, Incheon Power Generation Site Division and Sejong Power Generation Site Division are using a clean fuel, LNG, reducing the emissions of air pollutants, including SOx, fundamentally.

Flue Gas Desulfurization (FGD)

The environmental pollution prevention FGD facility absorbs 90-94% of the SOx occurring when fossil fuel is combusted and producing limestone slurry and react as a by product.

Selective Catalytic Reduction (SCR)

The SCR environmental facility contains an ammonia catalyst that reacts with NOx in exhaust gases and remove NOx after decomposing it into water and nitrogen (non-hazardous to human health).

Electrostatic Precipitator (EP)

The EP is a high-efficiency environmental pollution prevention facility that produces a negative electric charge on dust with the application of high-voltage DC power. The negatively-charged dust is attracted to the positively-charged collecting electrode, removing the dust from emissions.

Operate Comprehensive Wastewater Treatment Facilities & Introduced Latest Highly-Advanced Wastewater Treatment Technologies to Treat Wastewater Occurring at Power Plants.

Wastewater at power plants is generated from boiler water quality management, pure water production and DeSOx facility operation. To purify the wastewater, KOMIPO operates comprehensive wastewater treatment and DeSOx wastewater treatment facilities. For the DeSOx wastewater facility, in particular, Boryeong Power Generation Site Division, Shin Boryeong Construction Site Division and Seocheon Power Generation Site Division have introduced concentration evaporization facilities, a highly advanced wastewater treatment technology, and are taking the lead in the management of clean water resources.